Moreover, the power supply is concealed in the machine, making it much safer. UL Certified MeanWell Power Supply: Equipped with MeanWell power supply, produced by the listed company with mature technology, meeting all the needs of fast heating and long-time printing.

Ultimaker cura ender 3 v2 profile series#

The main selling point of Ender 3 series 3D printers is stable printing, mainly because of the use of V-belt pulleys, which ensure smooth movement, low noise, wear resistance, and longer printing life. It is longish but covers a lot of material.4.3 Inch Color LCD Screen, 32-bit Silent Motherboard, Carborundum Glass Platform, UL Certified Meanwell Power Supply, Print Resume Function, 220 x 220 x 250mm Print SizeĬreality Ender-3 V2 is great at your Best budget 3D printer. It a moderator here and has put together a VIDEO regarding bed adhesion. (Python is fussy about punctuation placement so I just changed the numbers instead of deleting the section. I had to share the folder with myself to be able to save the file. Change all the 108's to 117.5's leaving the negative signs in place. The stock file has "117.5"'s and "108"'s to define the disallowed areas. Now the disallowed areas are of zero width and effectively disappear. "machine_name": ,īecause I have my bed defined as 230 x 230 (useable area) I changed all the numbers in the disallowed area to 1/2 of 230. The Overrides section looks like this (when altered for my use):

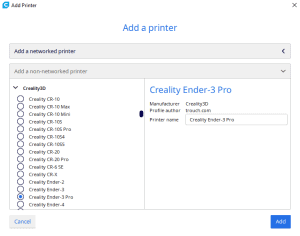

The file you need to alter is "Creality_" and is in the Ultimaker program folder ".\resources\definitions" and is a text file so you can open it with any text editor (like Notepad). You can't put a clip near the wire attachment point of the bed but it is included in the disallowed area. The "clip areas" are just rectangles across the front and the back. A lot of people seem to equate "Open Source" with "Non-Profit" but it isn't true. Ultimaker is gracious enough to include it. That third party submits the definition to Ultimaker for inclusion in Cura. So a printer company like Creality contracts with a third party ("" for Creality printers) to develop the printer definitions, extruder definitions, and base meshes (like the Ender logo that appears on the bed in Cura). That would be really dumb for a company that manufactures and sells it's own printers.

Ultimaker cura ender 3 v2 profile upgrade#

They would have to buy at least one of each machine, and upgrade them as a manufacturers made changes. "Also, I’m puzzled why there is still no specific profile for the Ender 3 V2?" It would be impossible for Ultimaker to write profiles for other manufacturers printers. That sets it back to the original orientation. What you can do is select the model, right click and "Reset all model Transformations". Rotation with snap off can't be recovered from (there is a GitHub request for a textbox so a person could enter an angle instead of using the grips, but it is deferred). You must alter that file to get rid of the clip areas. That defines the darker areas on the front and rear of the Cura build plate but they don't extend up the sides because you can't put clips there. If you rotate the part 45° it may fit on your build surface. In Cura - if you set the Build Plate Adhesion to Skirt and make it 1 loop and 1mm from the part it should then fit on your build surface. Select "Set Home Offset" and then "Save Settings" on the LCD. On the printer use the LCD to Auto-Home and then move the nozzle to a point 2.5mm in from the left edge and 2.5mm in from the front edge of the build surface (close is good enough) and at Z=0. In Printer Settings set the X width and Y depth to 230.

In the front and back you see darker gray areas that are defined as "disallowed areas" in your printer definition file and are not affected by skirt and brim settings.

Those are there because you have a skirt or brim defined and Cura is reserving those areas. If you look you will see that on the left and right of your Cura build surface there are lighter gray areas. Another thing that affects the size is skirts and brims. In addition, there are "disallowed areas" defined for the clips that hold the glass down (there were on my Ender 3 Pro). Creality calls it a 220 x 220 build surface and that's what "Trouch.Com" (the developer of the Creality printer definition files) put in for all the Ender 3's.

0 kommentar(er)

0 kommentar(er)